To achieve excellence in quality control laboratories, more is required than just routine testing and compliance. A structured approach is needed to identify inefficiencies, align teams, and build a foundation for sustainable improvement. The diagnostic phase is the cornerstone of this process. By applying Kaizen principles, organizations can transform their QC operations into drivers of efficiency, reliability, and continuous improvement.

This guide provides a step-by-step approach to carrying out an effective diagnostic phase in quality control (QC) laboratories.

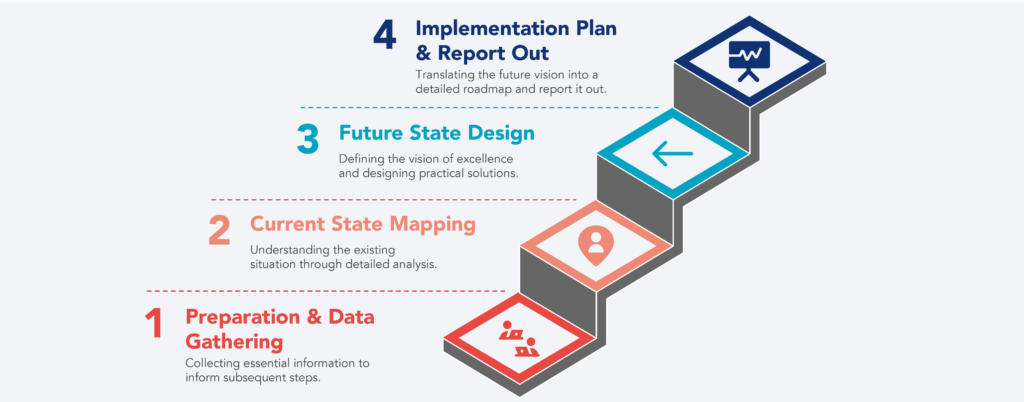

Figure 1 – Four-step staircase diagram of a diagnostic process

1. Preparation & data gathering

The diagnostic phase begins with thorough preparation and systematic data collection. At this stage, the goal is to establish a strong foundation by aligning teams, clarifying objectives, and gathering the critical information required to understand current challenges.

Project preparation

The success of any diagnostic phase begins with thorough project preparation. This includes defining a clear agenda, selecting the right team, assigning responsibilities, engaging key stakeholders, and setting up logistics. A well-structured kickoff not only establishes alignment on objectives and expectations but also builds early commitment, ensuring that the entire team is motivated and prepared to drive the process forward.

Data gathering

The next step is to collect relevant process information. This includes workflow details, workload volumes, turnaround times, error rates, and resourcing patterns. Capturing this data creates the baseline for analysis and highlights where the biggest inefficiencies may lie.

Voice of the customer

Listening to stakeholders is crucial. Through a Voice of Customer (VoC) exercise, the pain points of internal customers, lab staff, and management are captured. This not only provides valuable insights into satisfaction and expectations but also fosters engagement by giving stakeholders a voice in shaping the improvement agenda.

The VoC assessment combines both quantitative and qualitative analysis. On the one hand, surveys and structured interviews measure the gap between importance and satisfaction across key dimensions. On the other hand, typical VoC analysis compares performance across key vectors such as accessibility and responsiveness, business knowledge, solution orientation, user friendliness of solutions, and customer orientation. This enables organizations to identify strengths and weaknesses. The VoC highlights not only key improvement opportunities but also positive aspects that should be preserved.

Data analysis

Collected data is transformed into actionable insights that serve as the foundation for team discussions. Using tools such as control charts, capability analysis, and boxplots, variability and bottlenecks are identified. This structured preparation of insights ensures that improvement opportunities are clearly highlighted and provides a fact-based starting point for prioritizing actions during the diagnostic phase.

Benchmark

Benchmarking provides an external perspective to complement internal analysis. It combines a literature review, company interviews within the same sector, cross-industry comparisons, and insights from information systems. This approach allows QC laboratories to identify best practices, understand performance gaps, and capture innovative solutions that may not yet exist internally. By comparing against both peers and different industries, organizations ensure that improvement opportunities are ambitious yet achievable.

Unlock excellence in your QC labs with a structured diagnostic approach

2. Current state mapping

Once preparation and data gathering are complete, the next step is to develop a deep understanding of how the QC laboratory currently operates. Current state mapping provides a holistic view of processes, resources, and performance, enabling teams to visualize inefficiencies and uncover improvement opportunities.

Introduction

To ensure alignment, the diagnostic phase often starts with an introduction to Kaizen. This step equips teams with the mindset and tools needed to critically analyze current operations and actively participate in designing improvements.

Material and sample flow analysis

Mapping the flow of materials and samples provides a clear picture of how work progresses through the laboratory. It helps identify bottlenecks, delays, redundancies, and unnecessary handovers that increase lead time. By visualizing each step — from sample reception to reporting — teams can distinguish between value-added and non-value-added activities, quantify waiting times, and uncover inefficiencies that are often hidden in daily routines. This analysis is essential to reduce waste, balance workloads, and ultimately shorten turnaround times.

Strategic planning analysis

QC laboratories must be closely aligned with business and production priorities. Strategic planning analysis examines how resources are structured to respond to different demand scenarios and assesses whether the organizational model is fit for purpose. It also reviews the utilization of test methods, identifying possible alternatives that can optimize capacity and reduce bottlenecks. This ensures that the laboratory operates not only efficiently in the present but is also prepared to adapt to future changes in demand.

Efficiency improvement analysis

At this stage, teams evaluate efficiency by identifying non-value-added tasks, excessive waiting, or rework. Shadowing and time studies are particularly valuable in uncovering inefficiencies that remain hidden in reports.

The analysis also looks at workflow optimization, including logistics, task balancing, lab layout, and visual management. In parallel, data management practices are assessed, from record-keeping and digital flow to instruments’ integration and analysis tools. Finally, the level of automation in high-volume testing is reviewed to identify opportunities for faster, more reliable execution.

Execution planning analysis

Execution planning focuses on how laboratory capacity is scheduled and distributed. It evaluates whether resources — personnel, equipment, and consumables — are allocated effectively and whether tasks are prioritized according to service level agreements (SLAs) and business priorities.

The analysis also verifies the conditions regarding capacity availability, such as the skills matrix of the team, equipment maintenance, and inventory management. When planning is misaligned, bottlenecks and delays occur; when optimized, it ensures balanced workloads, reliable turnaround times, and improved overall performance.

Possible scenarios quantification

To support decision-making, different scenarios are quantified. For example, what happens if demand increases, or if resources are redistributed? This step allows for fact-based discussions on how to improve resilience and adaptability.

3. Future state design

With a solid understanding of the current situation, the focus shifts to designing the desired future state. This phase empowers teams to envision what excellence in QC operations should look like and to translate that vision into actionable solutions.

Kaizen methodology training

Before moving to solution design, teams are trained in Kaizen methodology. This ensures that everyone shares a common understanding of Lean principles, waste elimination, and continuous improvement practices.

Defining what winning looks like

Through a “blank sheet” exercise, the team defines the ideal future state — what excellence looks like in their QC operations. This vision sets the direction and motivates stakeholders to work toward a shared goal.

Solutions design & quantification

In this step, solutions are co-created to close the gaps identified during the diagnostic phase. These can include new standards of operations, redesigned workflows, or the introduction of digital tools to streamline processes. Solutions are grouped into opportunity clusters, ensuring they address both quick wins and long-term structural improvements.

Whenever possible, mockups and pilots are developed to test and validate new processes before full-scale implementation. Each solution is then quantified in terms of cost, expected benefits, and impact on key performance indicators, ensuring feasibility and alignment with business objectives.

4. Implementation plan & report out

The final phase of the diagnostic journey transforms the designed solutions into specific Kaizen Events supported by a robust business case. This ensures that improvement initiatives move seamlessly from design to execution, with clear justification, measurable impact, and strong organizational alignment.

Solutions prioritization

Not all solutions can be implemented at once. Prioritization is key, balancing quick wins with medium and long-term initiatives. This ensures momentum is maintained while laying the groundwork for sustainable improvements.

Implementation plan

A detailed implementation plan translates the future state vision into actionable steps. It defines clear deliverables, responsibilities, and timelines, while linking each initiative to measurable success metrics.

Governance structures and ownership are established to ensure accountability, and activities are prioritized according to their impact and feasibility. Each initiative typically follows four phases — preparation, intensive workshops with implementation, ramp-up, and stabilization — ensuring that improvements are embedded sustainably into daily operations.

Accelerate efficiency in pharma and medical device organizations

Cost and benefit analysis

Each initiative undergoes a cost-benefit assessment. This helps management allocate resources wisely and provides transparency on expected returns, often including ROI calculations to demonstrate financial impact.

Business case and final report out

The diagnostic phase concludes with the development of a business case that consolidates the identified opportunities, solutions, expected benefits, costs, and ROI. This provides a clear rationale for investment and prioritization.

The outcomes are then presented in a formal report out session: first to senior management to validate recommendations, and subsequently to a broader group of stakeholders to ensure transparency, alignment, and commitment to the next steps of implementation.

Sustainable results and long-term excellence

A well-executed diagnostic phase enables laboratories to uncover inefficiencies, align teams, and design future-ready solutions supported by clear business cases. Essentially, it relies on the active participation of laboratory teams throughout the process, ensuring that improvements are both practical and embraced by those who will implement them.

More than a one-time assessment, the diagnostic phase provides a roadmap for measurable improvements in performance, compliance, and reliability. And it is only the beginning. Its true value emerges in the implementation phase, where prioritized solutions are executed, monitored, and stabilized — turning design into sustainable results and long-term excellence in QC operations.

See more on Pharmaceuticals

Find out more about transformation in this sector