Case Study

From crisis to excellence: the impact of an operations management system on logistics

Goals : develop and implement a Lean operating system to restore performance in a critical operation and ensure long-term operational excellence

>16M €

Total accumulated savings

+15 %

Gross profit in the pilot operation

28 %

Performance improvement

In a context of underperformance and the latent risk of a strategic logistics operation coming to a halt, this international organization developed its own Lean logistics system. The goal was to address complex operational challenges and scale best practices across its global footprint.

This case study focuses on the creation and consolidation of an operations management system. The implemented approach—and the breakthrough results achieved in a single operation—quickly became a benchmark for the entire group.

Excellence in global and national logistics management

The company is part of the world’s largest logistics services group, positioning itself as a global benchmark in integrated supply chain management. With a presence in over 200 locations and a global workforce of approximately 200,000 employees, the organization delivers customized warehousing and transportation solutions by combining international expertise with local experience.

This organization has approximately 20,000 employees and over 80 operational centers, providing an extensive logistics infrastructure with millions of square meters of warehouse space. It stands out as a leading warehouse management provider for multiple industries, serving nearly 200 clients in sectors such as automotive, chemical, energy, engineering, healthcare, retail, and technology. Its distinguishing feature is that it is one of the only logistics operators with the capacity to integrate the entire supply chain, combining operational excellence and proximity to the customer in all its solutions.

Laying the groundwork for operational excellence

In 2023, with a team of roughly 300 employees, this operation—less than a year after its launch—was facing alarming operational and financial results. Gross profit stood at -23.1%, significantly below the internal benchmark of 13%. Absenteeism reached 8.89%, and operational turnover was at 6.86%, while the targets for both indicators were set at 2% and 2.5%, respectively. The operation was also struggling to meet contractual SLAs, putting the business’s continuity at risk.

Faced with this scenario, the organization recognized the urgent need to design a structured logistics management model capable of quickly reversing the situation and establishing a sustainable foundation for continuous improvement. It was within this context that the development of an operations management system began, designed to align strategy and operations through a company-wide Lean approach.

Reach a new level of excellence in your company’s logistics operations

Translating strategic goals into practical actions

One of the main challenges was the lack of alignment between the organization’s strategy and its on-site implementation. It was essential to ensure that global objectives were translated into practical, measurable actions that operational teams could carry out.

Misaligned organizational structure

The existing structure made it difficult to deliver results consistently. Responsibilities were not clearly defined, and the organizational model did not allow performance to be monitored effectively, nor did it enable operational improvement routines to be sustained.

Limited performance visibility and management

The operation lacked a robust performance measurement system. Without standardized indicators or regular review cycles, it was challenging to identify deviations or make informed decisions.

Lack of standardization and skills development

Processes were not standardized, leading to inconsistencies in execution and poor reliability. Additionally, teams lacked access to an ongoing technical training program, which was necessary to ensure the qualifications required for efficient operations.

Need to foster a culture of continuous improvement

At the time, there was no structured culture of continuous improvement. Teams rarely took part in identifying problems or suggesting solutions. Improvements occurred sporadically and reactively, without a straightforward method or long-term sustainability.

Lean logistics in practice: structuring and execution

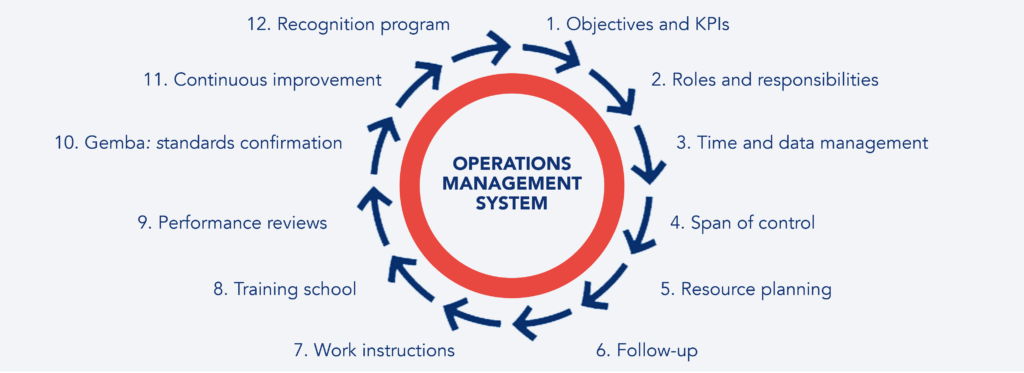

To address the critical challenges within the operation, an operations management system was developed and implemented—a Lean operating model designed to structure, standardize, and sustain complex warehouse operations. Implementation followed a detailed roadmap, formalized as a reference guide outlining the system’s principles and key elements. In parallel, a phased deployment plan was defined, tailored to the reality of Lean warehouse operations and focused on building autonomous, high-performing teams.

Clear link between strategy and operations

To address the lack of alignment between strategic objectives and on-site actions, a structure of logistical objectives and KPIs was created, enabling the translation of strategy into tangible metrics visible at all organizational levels. This approach was implemented by developing a performance and productivity indicator tree, which enables the breakdown of group-level targets into area- and team-level objectives.

Figure 1 – Outline of the project’s objectives

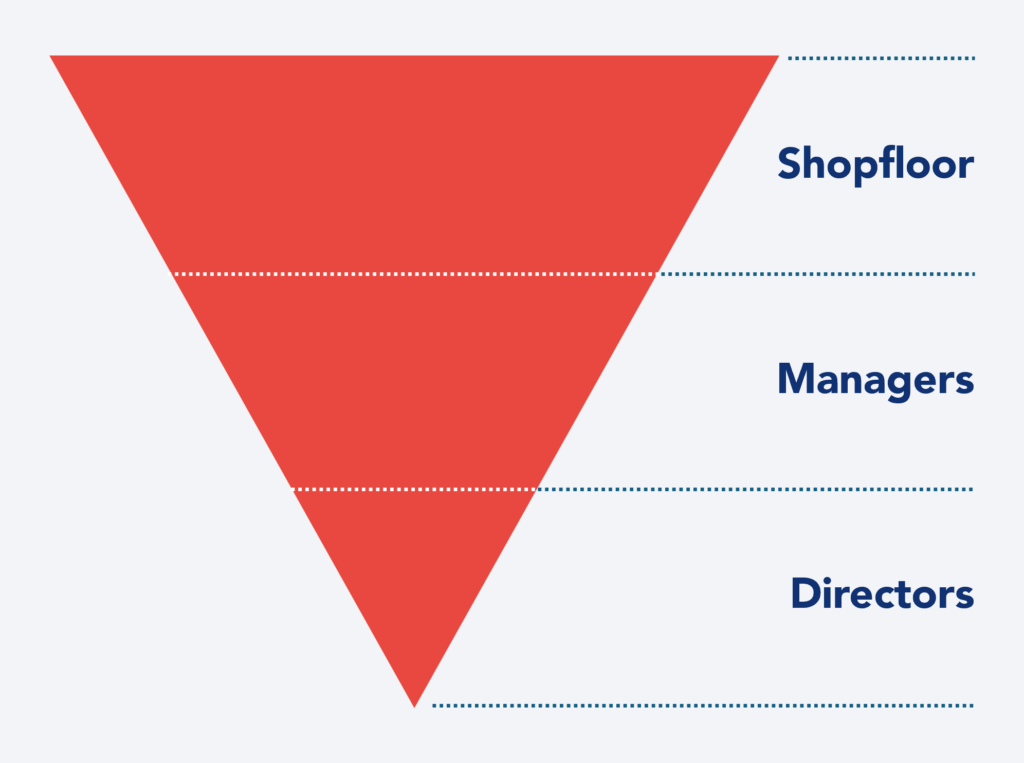

Strengthening the organizational structure

The new organizational structure ensured an appropriate span of control, enabling the consistent execution of routines tied to the newly implemented system. Clear role and responsibility assignments were established, ensuring that every hierarchical level understood its contribution to operational results. This clarity was essential for maintaining discipline in daily operations and building a strong foundation for accountability.

Figure 2 –Schematic of the involvement structure in the new operational management system

Systematic performance management

Performance measurement and monitoring became part of the daily routine through a structured monitoring system. This system included specific tools to monitor productivity, effective hours, and performance by operator, process, and area.

At the same time, a measure has been implemented regarding performance feedback sessions, which include:

- Individual weekly feedback.

- Tactical meetings by shift.

- Weekly and monthly strategic reviews.

These practices have fostered a culture of accountability and performance improvement, based on data, dialogue, and rigorous monitoring.

Process standardization and ongoing skills development

The operation adopted documented work standards, structured as standardized operating procedures focused on efficiency, safety, and quality. To sustain this standardization, a training academy was established, featuring simulation centers and structured continuous training programs. Employees now receive practical training from trainers who work directly on-site, thereby reinforcing the skills that directly contribute to process consistency and supply chain efficiency. Meanwhile, leaders have been trained in specific management tools.

Create your own personalized academy and empower your teams to achieve breakthrough results

Additionally:

- Each frontline employee receives an average of 4.3 hours of continuous training per month.

- 2.2% of total working hours are dedicated to training.

- Leaders dedicate 5.7% of their annual time to training in the new operations management system, totaling 134 hours per leader.

All employees have access to digital learning content through the internal online platform, with a strong focus on Lean modules. Notably:

- Each employee completed 20 hours of online training in Lean tools.

- A total of 730 employees were trained as specialists in continuous improvement (CI) tools, significantly strengthening the organization’s technical capabilities across all operational areas.

Figure 3 – Training academy

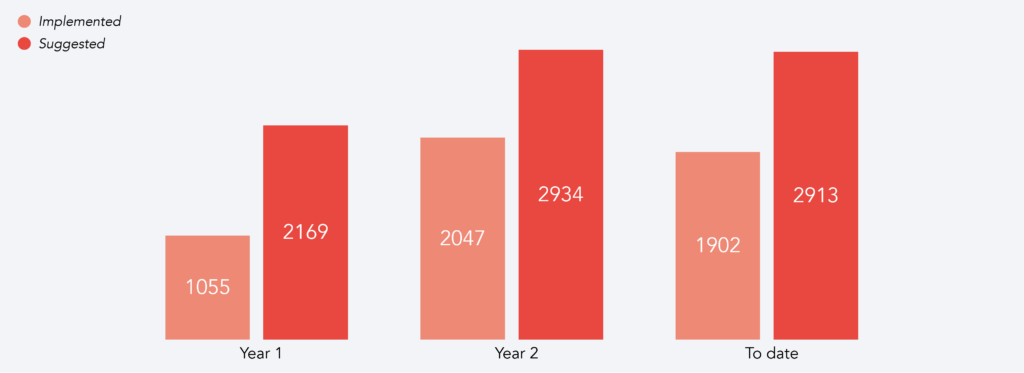

Fostering continuous improvement within teams

To encourage active team participation, idea suggestion programs and continuous improvement groups were introduced in logistics. These groups focused on identifying and solving problems that directly impacted operations. They developed structural projects that improved processes, using Kaizen methodologies and involving frontline operators. This shared improvement mindset became one of the system’s pillars.

Leadership engagement on the floor

Leadership at all levels became actively involved in operations through the systematic practice of Gemba Walks. This approach strengthened visual management in logistics, aiming to verify standard execution, identify deviations, and provide close support to teams. Gemba Walks became a central element of the new management system’s culture, ensuring alignment between planning and execution.

Recognition culture driving continuous improvement

To strengthen motivation and reinforce consistent behaviors, a recognition program was developed to reward both individual and team performance. The criteria used covered safety, quality, performance, and contribution to continuous improvement, thus recognizing not only results, but also commitment to the system’s culture.

Results of the operations management system implementation

The implementation of the new system brought about a profound transformation of the logistics operation in focus. In less than a year, results marked a clear turning point in the unit’s performance and the strategic positioning of the model on a global scale.

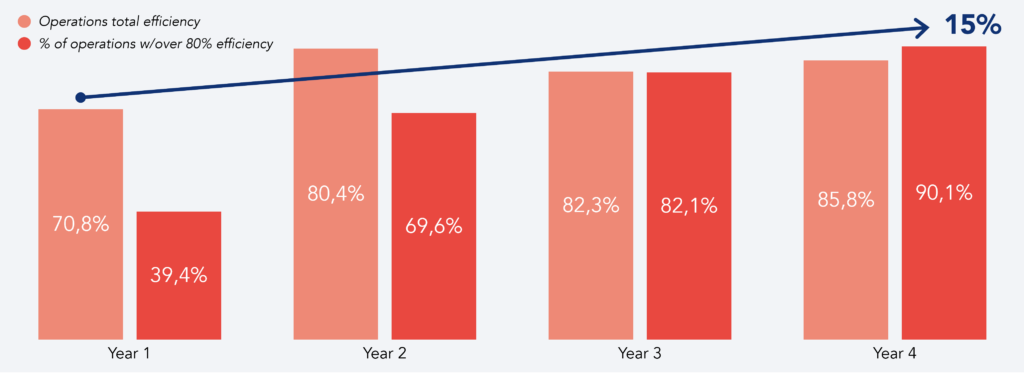

In the pilot operation, the gains were significant: gross profit increased from -23.1% to +15%; operational turnover dropped from 6.86% to 0.86%; and absenteeism decreased from 8.89% to 2.1%. These sustained results confirmed the effectiveness of the model and led to its official adoption as the organization’s global operating system.

Figure 4 – Graph showing the evolution of operational efficiency levels

After implementing the system and analyzing the results achieved, the organization launched its international expansion plan. Leadership teams from various countries, including representatives from Toyota, visited the site, recognizing the practical value of Lean principles applied in the logistics sector.

The consolidation of this management system has demonstrated its effectiveness in warehouse optimization, with a direct impact on productivity, training, and team maturity. Over the years, performance indicators have reflected a high level of operational maturity and impact:

- 80 warehouses with the logistics operations management system fully implemented.

- 4,300 employees monitored through performance tracking tools.

- 570 frontline leaders applying system routines daily.

- 720 employees trained in continuous improvement tools (VSM, MASP, SMED, Time and Method Studies, and Management System Foundations).

- Over 700 Kaizen initiatives completed.

- 40 Value Stream Mapping (VSM) projects developed.

- 490 Gemba Walks conducted by team leaders, directors, and managers.

- 28% increase in operational performance capacity over three years.

The commitment to continuous improvement has remained strong over the following years, with growing activity volumes:

- In the first period, approximately 1,050 Kaizen initiatives were carried out; a year later, that number rose to over 2,000; and in the following year, around 1,900 additional initiatives were completed.

- 750 Gemba Walks were held, representing an increase of 80% on the previous year.

- Over 150 Kaikaku projects with direct customer impact implemented in the same year.

- More than 1,300 employees trained in the new system and its tools, including over 500 leaders and approximately 700 continuous improvement specialists.

Figure 5 – Graph showing the number of improvement actions implemented

As a result, the logistics management system became one of the pillars of the organization’s global strategy and was integrated into the international executive committee. It has also been adopted as a differentiating factor in negotiation processes with new clients and when renewing contracts, thanks to its proven ability to generate savings, sustainably improve warehouse productivity, and strengthen internal commitment. This contribution was essential to the company’s recognition as one of the best places to work in its country.

Today, the model is implemented in more than 500 operations worldwide, with accumulated savings of over €6 million.

This case illustrates how structured changes— even those that begin with simple actions—can trigger profound, lasting transformations. The establishment of routines, the daily involvement of teams, and the disciplined adoption of Lean practices significantly elevated operational maturity. The impact achieved has become a benchmark and a source of inspiration for a wide range of organizations, including internationally recognized companies, seeking to evolve their operating models in pursuit of excellence.

We are committed to respecting our clients’ confidentiality. While we have altered or omitted their names, the results are genuine.

See more on Logistics

Find out more about transformation in this sector

See more on Operations

Find out more about improving this business area