In an organizational context where variability, defects, and waste directly undermine competitiveness, it becomes essential to adopt methodologies that enable consistent and measurable process improvement. DMAIC (Define, Measure, Analyze, Improve, Control) stands out as the core framework of Six Sigma projects and is widely used to solve and optimize processes, address chronic problems, and ensure long-term quality.

The DMAIC methodology represents a disciplined, data-driven, and results-oriented way of thinking. In this article, we explore why this approach remains a benchmark in continuous improvement projects, regardless of the industry or the organization’s size.

Introduction to DMAIC

DMAIC is the process used in Six Sigma projects to guide teams from problem identification through to stabilization and control. To fully understand the value and applicability of the DMAIC model, it’s essential to explore its foundational concept, its origin in Six Sigma, and how it integrates with operational excellence approaches.

What is DMAIC?

DMAIC is a structured process improvement methodology focused on solving complex problems using data and statistical analysis. It consists of five sequential phases: Define, Measure, Analyze, Improve, and Control. Each phase has specific objectives, deliverables, and tools that help improvement teams systematically identify and eliminate inefficiencies, variations, and root causes of process failures.

Unlike ad hoc approaches, DMAIC promotes disciplined, evidence-based decision-making, ensuring that implemented changes are not only effective but also sustainable over time. This approach is applicable across all industries and can be used to address a wide range of operational challenges, from defects in industrial processes to inefficiencies in administrative services.

The origin of DMAIC in Six Sigma

The DMAIC cycle emerged in the context of Six Sigma, a quality management methodology introduced by Motorola in the 1980s. Its goal was to drastically improve process performance by reducing variability and defects. The approach was later refined and widely adopted by General Electric, which made it a cornerstone of its operational excellence strategy.

Six Sigma aims to achieve high levels of quality, traditionally defined as 3.4 defects per million opportunities (DPMO), with a focus on statistical stability and process capability. DMAIC was designed as the operational roadmap for Six Sigma projects, ensuring a rigorous and replicable execution.

Each phase of DMAIC is associated with specific tools and techniques, such as SIPOC, FMEA, and DOE (Design of Experiments), among others, that reinforce its data-driven approach to performance improvement.

The relationship between DMAIC, Six Sigma, and Lean Six Sigma

DMAIC is the central execution model for Six Sigma projects, serving as a structured framework for reducing variation, improving quality, and increasing customer satisfaction.

When Six Sigma is combined with the principles of Lean Thinking, which focus on eliminating waste, improving flow, and maximizing customer value, the result is Lean Six Sigma. In this context, DMAIC remains the foundational structure for improvement efforts but is complemented by Lean Management tools in each phase, expanding the team’s problem-solving capabilities. The integration of Lean and Six Sigma, supported by DMAIC, provides organizations with a powerful and balanced approach.

Interested in deepening your knowledge of Lean Six Sigma?

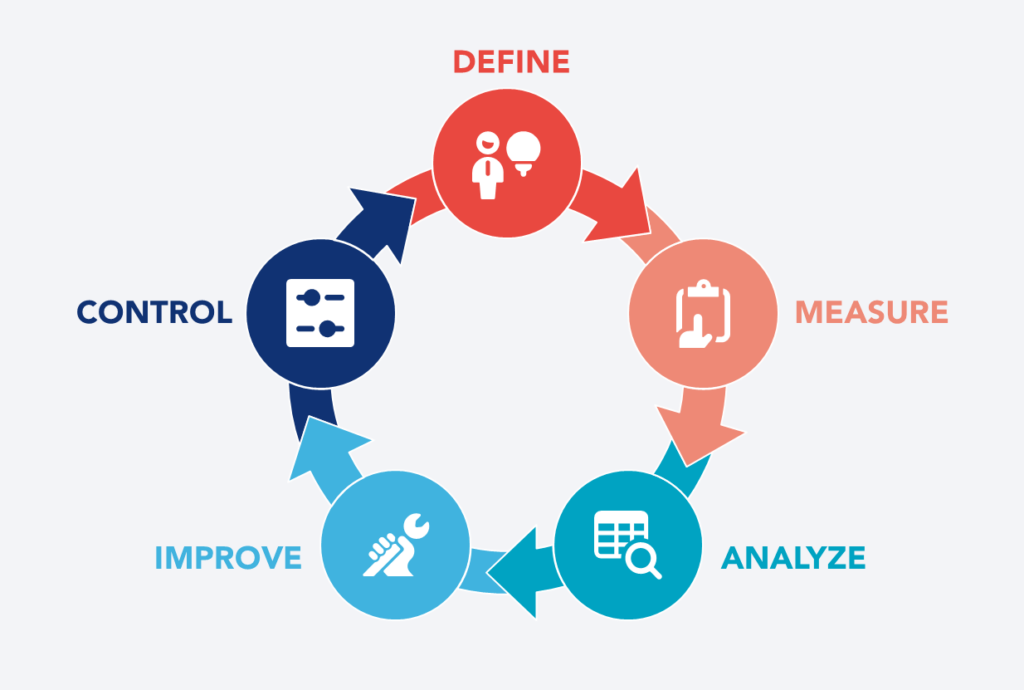

Steps of the DMAIC cycle

Each phase of the DMAIC approach has clearly defined objectives, specific tools, and gate criteria that ensure analytical rigor and the effectiveness of proposed solutions. Below, we outline each stage of the DMAIC cycle, highlighting its purpose, key activities, and contribution to achieving robust and sustainable results.

Figure 1 – DMAIC process

Define: Define the problem and the project objectives

The Define phase lays the foundation for the improvement project. Its main goal is to clearly define the problem to be solved, identify the stakeholders involved, and align expectations regarding the desired outcomes. This phase involves tools such as the Project Charter, SIPOC (Supplier–Input–Process–Output–Customer), CTQs (Critical to Quality), and the definition of preliminary performance indicators.

A clear and shared definition of the problem is crucial to ensuring focus, preventing scope creep, and facilitating the engagement of both improvement teams and top management.

Measure: Measure current performance and collect data

The Measure phase aims to quantify the current state of the process and establish a reliable baseline. Once the problem is defined, the DMAIC team must determine which relevant data to collect, define consistent measurement methods, and assess the process’s capability and stability based on real data.

Common tools include Capability Analysis, control charts, histograms, and value stream mapping. The reliability of the data collected at this stage is crucial for the strength of the subsequent analyses.

Analyze: Analyze root causes of problems

In the Analyze phase, the focus shifts to identifying the root causes that explain the observed variability, defects, or inefficiencies. This analysis should be thorough, supported by both statistical and qualitative methods that allow hypotheses to be validated objectively.

Frequently used tools include the cause-and-effect diagram (Ishikawa), 5 Whys, regression analysis, correlation analysis, and statistical significance testing. The goal is to avoid superficial solutions by addressing the critical variables that impact process performance.

Improve: Develop and implement effective solutions

Once the root causes are identified, the Improve phase focuses on developing, testing, and implementing solutions that eliminate or reduce the identified issues. This phase encourages idea generation, experimentation (e.g., through DOE – Design of Experiments), and validation of proposed improvements.

Engaging operational teams and employing approaches such as Kaizen Events, rapid prototyping, or controlled pilots is crucial to ensure that solutions are viable, sustainable, and scalable. Improvements should be evaluated against the performance indicators defined in previous phases.

Control: Controlling and sustaining results

The final phase of the cycle, Control, aims to ensure that the improvements are sustained and that the process does not revert to its previous state. This involves implementing continuous monitoring systems, updating standard operating procedures (SOPs), and establishing response plans in case of deviations.

Tools such as control charts, control plans, internal audits, and performance dashboards are applied. Leadership involvement and the empowerment of frontline teams are key to maintaining control and fostering a culture of continuous improvement.

How to apply DMAIC in practice

Although the DMAIC cycle is a structured and standardized methodology, its practical application can vary depending on the industry, the organization’s maturity level, and the complexity of the problems being addressed. The effectiveness of this approach is closely tied to the appropriate selection of tools in each phase, the engagement of cross-functional teams, and leadership’s ability to drive change.

Evolution of DMAIC tools used at each phase

Applying DMAIC requires mastery of specific tools that vary based on the level of Six Sigma training and certification (Yellow Belt, Green Belt, Black Belt). As professionals advance through certification levels, they gain access to more sophisticated analytical tools, enabling them to tackle increasingly complex challenges.

The image below summarizes the progression of tools taught at each stage of the DMAIC cycle, based on certification level:

- Yellow Belts learn from fundamental tools such as SIPOC, CTQ, FMEA, PDCA, root cause analysis, and SPC (Statistical Process Control).

- Green Belts evolve to techniques such as Gauge R&R, DOE (Design of Experiments), advanced statistical analysis, Poka Yoke, Jidoka, and the development of robust control plans.

- Black Belts master complex approaches such as DFSS (Design for Six Sigma), advanced simulation, multivariate analysis, and multi-process control plans.

This evolution ensures that organizations can build scalable internal capabilities with the flexibility to respond to increasingly demanding operational and strategic challenges.

The role of teams and leadership in DMAIC projects

The success of a DMAIC project depends on more than just methodology or tools used. The human factor is critical for ensuring alignment, execution, and the long-term sustainability of results. Three roles are particularly crucial in Six Sigma projects:

- Project leader: Responsible for leading the DMAIC project in a structured way, applying the right tools at each phase, ensuring objectives are met, and promoting data-driven decision-making. This professional must be certified in Six Sigma or Lean Six Sigma with strong technical, analytical, and facilitation skills.

- Project team: Should be cross-functional and trained in the tools relevant to their certification level. A diverse team brings multiple perspectives, aiding in the identification of root causes and the development of robust solutions.

- Champion (Executive sponsor): Ensures the project is aligned with organizational strategy and removes roadblocks by allocating necessary resources.

- Process owner: Takes responsibility for implementing and ensuring continuity of improvements in day-to-day operations.

In addition, leadership plays a fundamental role in fostering a culture of continuous improvement, leading by example, supporting training and experimentation, and recognizing sustainable results.

Benefits of the DMAIC approach

Adopting the DMAIC cycle offers organizations a range of strategic and operational benefits, particularly in quality management, process stability, and resource efficiency. By providing a disciplined structure for solving complex problems, DMAIC becomes a foundational pillar for Lean Six Sigma initiatives and operational excellence.

Improving quality and reducing waste

DMAIC targets the root causes of defects and inefficiencies, leading to tangible improvements in product and service quality. By reducing variability and standardizing processes, organizations achieve more stable and predictable performance, minimizing rework, waste, and non-compliance.

Tools such as FMEA, DOE, and Poka Yoke help prevent errors from occurring rather than just detecting them after they have had an impact. This focus on prevention leads to higher customer satisfaction and reduced non-quality costs.

More broadly, Six Sigma reduces costs by systematically eliminating variability, rework, and recurring failures — factors that directly impact operational efficiency and profitability.

Data-driven decision-making

One of DMAIC’s key differentiators is its emphasis on decision-making supported by reliable data and statistical analysis. Each phase of the cycle involves specific techniques to ensure that decisions are based on quantitative evidence rather than assumptions or subjective perceptions.

This approach builds greater confidence in proposed solutions, helps prioritize high-impact actions, and strengthens the credibility of improvement projects at the management level. The analytical culture fostered by DMAIC enables organizations to become more performance-oriented, capable of identifying deviations quickly and responding with precision and agility.

Sustaining results and fostering a culture of continuous improvement

Unlike one-off initiatives, DMAIC embeds control and continuous monitoring mechanisms that help sustain improvements over time. The Control phase introduces control plans, dashboards, and performance indicators that allow teams to track process performance in real time and respond swiftly to deviations.

Moreover, the DMAIC cycle reinforces a culture of continuous improvement by encouraging cross-functional teams to identify opportunities, solve problems, and drive organizational learning. Its repeated application builds internal capabilities and strengthens practices that support innovation and organizational resilience.

Find out how to apply DMAIC in your organization with expert support

Conclusion: Why DMAIC remains relevant

DMAIC continues to stand out as one of the most robust and effective approaches for structured problem-solving and quality improvement. Its sequential logic, emphasis on statistical analysis, and focus on sustainable results make it highly applicable across industries and organizational sizes.

Over the years, DMAIC has proven its ability to reduce variability, eliminate waste, improve customer satisfaction, and increase process reliability. Its integration with Lean and Six Sigma methodologies further amplifies its impact, making it a central component in building cultures oriented toward operational excellence in both industrial operations and services.

Beyond solving problems, the DMAIC methodology empowers organizations to make data-driven decisions, develop internal talent, and sustain improvements over time. In a world of uncertainty, rapid innovation, and pressure to drive efficiency, solid methodologies like DMAIC are not just relevant: they are essential.

Still have some questions about DMAIC?

What is the difference between DMAIC and DMADV?

Both DMAIC and DMADV are Six Sigma methodologies, but they serve different purposes:

- DMAIC (Define, Measure, Analyze, Improve, Control) is used to improve existing processes that show performance issues or excessive variability.

- DMADV (Define, Measure, Analyze, Design, Verify) is applied when creating a new process, product, or service that must be designed from the ground up with a strong focus on quality and customer needs.

In short, DMAIC is used for optimizing and correcting existing processes, while DMADV is for designing with excellence from the start.

What is the difference between PDCA and DMAIC?

PDCA and DMAIC are both structured continuous improvement methodologies used to solve problems and optimize processes. However, they differ in their depth, the complexity of tools used, and the types of problems they address:

- PDCA (Plan, Do, Check, Act) is a simple, iterative cycle widely used in Lean and Kaizen contexts, ideal for implementing predefined improvements.

- DMAIC (Define, Measure, Analyze, Improve, Control) is a more robust and analytical approach that begins with problem definition and includes advanced statistical tools in each phase. It forms the backbone of Six Sigma projects and is particularly effective in solving complex problems with unknown causes or high variability.

In summary, the PDCA approach is best suited when the root cause is already known and a solution needs to be implemented or tested quickly. DMAIC is recommended when you need to thoroughly understand and analyze a problem to define an effective improvement solution.

Who should lead a DMAIC project?

DMAIC projects should be led by professionals certified in Six Sigma (Green Belts or Black Belts) or Lean Six Sigma, with skills in data analysis, project management, and problem-solving. However, project success also relies heavily on the active involvement of the Champion (executive sponsor), the Process owner, and a well-aligned, cross-functional team.

See more on Discrete Manufacturing

Find out more about transformation in this sector

See more on Process Manufacturing

Find out more about transformation in this sector