Companies need to operate efficiently, quickly, with high quality, and with environmental awareness, all at the same time. As a result, production systems play a strategic role in driving competitiveness, profitability, and continuous innovation.

This article reveals the core principles behind a high-performance production system, examines common mistakes that can undermine it, and explores the most effective approaches for building stable, flexible, and customer-focused operations. From continuous improvement to Industry 4.0 technologies, including sustainability, this guide demonstrates how to turn challenges into real, long-term performance.

Understanding the fundamentals of a manufacturing production system

Understanding the concept of a production system, its core components, and how its design impacts a company’s overall performance is essential for building more efficient, stable, and customer-focused operations. This understanding is the starting point for any journey toward operational excellence and continuous improvement.

What is a production system and why it matters for manufacturing efficiency

A production system is a structured set of processes, practices, resources, and methods that enable the efficient and high-quality transformation of raw materials into finished products. In today’s industrial landscape, operational efficiency, waste reduction, and delivering customer value are critical goals. A well-designed production system is the key to achieving them.

Lean production systems, inspired by the Toyota Production System (TPS), are designed to eliminate waste (Muda), variation (Mura), and overload (Muri), thereby creating stable, predictable, and flexible operations. Their value lies in their ability to reduce operating costs, ensure consistent quality, shorten lead times, lower working capital requirements, and enable quick adaptation to market demands.

Key components of Lean Manufacturing production systems

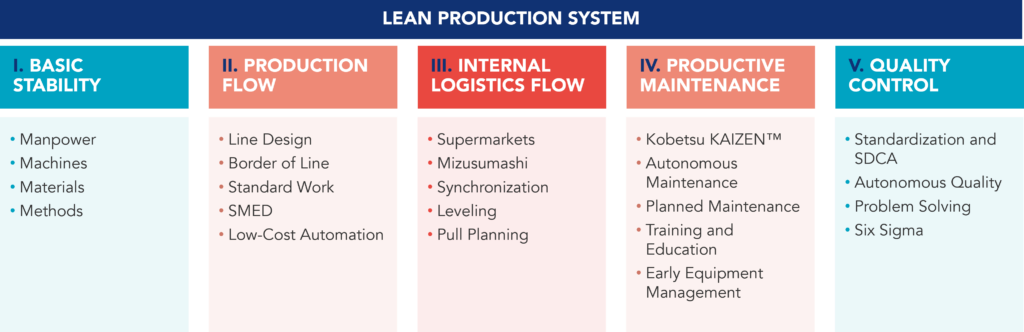

A Lean production system is built on five foundational pillars that together promote operational stability, continuous flow, reliability, and continuous improvement.

I. Basic stability

Before pursuing improvements, it’s essential to ensure stability in the core elements of the production process. Basic stability is rooted in the standardization and predictability of the 4Ms (Manpower, Machines, Materials, and Methods), creating a solid foundation for building a reliable and robust production system.

II. Production flow

True efficiency gains occur when workflows are uninterrupted. This pillar focuses on creating a continuous and balanced flow across operations through techniques such as efficient line design, eliminating idle time, and synchronizing activities. The smoother the process, the less waste is generated and the higher the productivity.

III. Internal logistics flow

Efficient production depends on equally efficient material supply. This pillar ensures the right materials arrive at the right place, at the right time, in the correct quantity, without excess or shortages. Applying concepts such as supermarkets, Mizusumashi, and pull systems helps synchronize logistics with the production pace, ensuring fluid and stable operations.

H4: IV. Productive maintenance

No production system can be efficient if its equipment is unstable or unreliable. This pillar aims to maximize equipment availability and performance by promoting a preventive and structured maintenance approach. Reliable machines form the backbone of safe and stable operations.

V. Quality control

Quality shouldn’t be assured only at the end of the line—it must be built into every step of the process. This pillar ensures that every team member contributes to getting it right the first time, using systems that detect and correct deviations in real time. By combining standardization with structured problem-solving, rework is avoided, and continuous quality improvement is promoted.

Figure 1 – Elements of a Lean Production System

How production system design impacts overall business performance

The design of a production system is one of the key drivers of operational performance and responsiveness in an industrial organization. A well-structured system not only ensures consistent operations but also supports agility and competitiveness in a constantly evolving market.

Some of the most significant impacts of a well-designed production system include:

- Waste elimination by reducing downtime, excesses, and process variability.

- Reduced response times, with less stock buildup and greater material flow.

- Higher quality at source, preventing errors and rework throughout the value chain.

- Better adaptability, even in highly unstable demand environments.

- Greater resource efficiency, with aligned and synchronized processes.

Beyond operational improvements, a well-designed production system strengthens a culture of accountability, structured problem-solving, and continuous improvement—core pillars of operational excellence. This operational stability leads to more reliable deliveries, fewer product defects, and a stronger ability to meet market needs. The result is a significant boost in customer satisfaction, sustained reduction in operating costs, and a direct increase in contribution margins, ultimately improving the overall profitability of the business.

Strategies for production system optimization

As we’ve seen, a Lean production system is grounded in the implementation of a set of principles, practices, and methodologies. The following sections explore in detail each of the five pillars previously outlined.

Discover the full potential of your production system with proven strategies

Lean Production System principles to maximize throughput

Lean, or continuous improvement, is not just a toolbox of methods, but a management approach that aligns the entire organization around creating value with minimal waste. The five core principles of Lean Thinking are:

- Create customer value: Clearly identify what constitutes value from the customer’s perspective, capture the voice of the customer, and improve their experience.

- Enable flow efficiency: Eliminate waste (Muda, Mura, Muri) across the value chain, aiming for one-piece flow pulled by customer demand.

- Be Gemba-oriented: Make decisions based on direct observation of processes at the actual location where value is created.

- Empower people: Involve team members at all levels, fostering skills, autonomy, and ownership.

- Be scientific and transparent: Use real data, experiment, validate, and standardize improvements to support a culture of structured problem-solving.

Production workflow improvements using continuous improvement techniques

Process flow is one of the core pillars of an efficient production system. Through Lean and Kaizen methodologies, it’s possible to identify and remove obstacles in both production and internal logistics workflows.

In production lines, key applied methodologies include:

- Optimized line and layout design to minimize movement and waiting time while promoting continuous flow.

- Border of Line design, with efficient availability of materials and appropriate sizing.

- Standard Work, which reduces waste at the workstation and ensures consistency in operations.

- SMED (Single-Minute Exchange of Die), to reduce setup times.

- Low-cost automation, delivering production efficiency through simple, effective solutions.

In internal logistics, material flow and stability are achieved through:

- Supermarkets, ground-level storage zones with visual management and easy access for picking, where replenishment is triggered by actual consumption.

- Mizusumashi, dedicated logistics operators who carry out frequent, standardized, light-load replenishment cycles, supporting rhythm and predictability.

- Process synchronization, enabled by systems like Kanban or Junjo, ensuring each step receives the right material at the right time.

- Production leveling, which aims to repeat production of a given product at consistent time intervals, enhancing system stability.

- Pull-based planning, a scheduling model driven by actual customer demand, avoiding early production and inventory buildup.

The importance of maintenance in production systems

Equipment availability and reliability are crucial for maintaining the stability of a production system. Total Productive Maintenance (TPM) involves the entire organization in asset care, combining autonomous, preventive, and proactive practices.

The most effective methodologies include:

- Kobetsu KAIZEN™, focused on eliminating specific equipment losses.

- Autonomous maintenance, where operators handle basic inspection and upkeep tasks.

- Planned maintenance, with clearly scheduled preventive interventions.

- Training and skill development, ensuring that everyone understands and applies best practices.

- Proactive management of critical equipment, reducing the risk of failure in key assets.

The role of quality control in sustainable production systems

Quality is a continuous process that must be embedded throughout the entire value chain. In a sustainable production system, quality control is integrated into the production flow, with an emphasis on defect prevention and rapid anomaly resolution.

Key approaches include:

- Standardization and SDCA (Standardize–Do–Check–Act) cycles, to ensure consistency and drive gradual improvement.

- Autonomous quality, using tools and matrices that empower operators to detect and correct defects on the spot.

- Structured problem-solving techniques to identify root causes and implement effective countermeasures that prevent recurrence.

- Six Sigma methodologies, to reduce process variation and achieve high levels of compliance.

Automation and AI integration in modern production systems

Automation and artificial intelligence have become central components in advanced production systems. Their integration boosts productivity, reduces errors, improves traceability, and enables real-time, data-driven decision-making.

Examples of application include:

- Collaborative robotics, assisting operators with repetitive or heavy tasks.

- Machine vision systems, enabling automated quality control.

- Predictive analytics, used to anticipate equipment failures and optimize maintenance.

- Smart manufacturing platforms, which adjust operational parameters based on performance data.

- Integration with MES/ERP systems, connecting production with value chain management.

Why production systems fail and how to avoid common pitfalls

Despite significant investments in developing production systems, many organizations fail to achieve the expected results. This often stems from inconsistent practices, a misplaced focus, or fragmented improvement efforts. Understanding the most common mistakes is essential for building production systems that are more robust, sustainable, and aligned with market realities.

Avoid production errors and implement sustainable systems

Focus on tools instead of practices and routines

A fundamental mistake that undermines the effectiveness of production systems is placing too much emphasis on tools while neglecting daily practices and consistent behaviors. In many organizations, the priority is to implement new tools, assuming that results will naturally follow. However, without active employee involvement, structured implementation, and ongoing discipline, these tools deliver little meaningful impact.

Sustainable change depends not only on introducing tools but on embedding new ways of working into daily routines. This requires regular practice and hands-on learning at the Gemba. It is through consistent practice that a culture of excellence is truly developed.

Focus on resource efficiency instead of flow efficiency

One of the most common production system mistakes is focusing on maximizing the utilization of resources—such as machines and operators—instead of ensuring a continuous and synchronized process flow. This mindset, rooted in the belief that keeping all resources constantly busy leads to greater efficiency, often results in large batch production, excess inventory between steps, and overproduction. This approach generates waste, masks operational issues, and results in rigid, unresponsive processes.

True efficiency is achieved by designing flows that respond to actual customer demand, without interruptions or unnecessary stock accumulation. A system designed around One-Piece Flow and driven by demand (Just in Time) improves quality, reduces lead times, and increases flexibility. Contrary to traditional thinking, efficiency does not begin with maximizing resource utilization; it begins with process flow. Only after ensuring flow should resources be optimized to sustain it.

Lack of system integration

Another common reason production systems fail is the implementation of isolated improvements, limited to specific workstations, departments, or processes, without considering their impact on the entire system. When improvements are made in a fragmented way, without alignment across functions, new bottlenecks appear, improvement efforts lose momentum, and best practices become difficult to scale or sustain. Over time, overall performance remains stagnant or deteriorates.

Avoiding this pitfall requires a systemic approach to improvement. It’s essential to coordinate actions across all components of the production system, ensuring that each intervention genuinely contributes to the robustness of the flow and value chain. Most importantly, people must be engaged, committed, and actively involved in the transformation process. Lasting change occurs when a Kaizen Culture is deliberately built. Transformation is only sustained when improvement becomes truly integrated and organization-wide.

Emerging technologies and future directions in production systems

The evolution of production systems is deeply connected to technological advancement and the growing demand for efficiency, flexibility, and sustainability. With the rise of Industry 4.0, production is no longer just a sequence of physical operations—it now integrates data, connectivity, and artificial intelligence. To remain competitive, organizations must adapt their systems to this new paradigm, leveraging emerging technologies to achieve higher levels of performance and resilience.

How to adapt production systems to Industry 4.0 and to smart manufacturing

Industry 4.0 marks a structural shift in how production systems are designed and managed. Connectivity between machines, systems, and people enables smart, highly responsive, and increasingly autonomous processes. To adapt to this new reality, production systems must be redesigned to incorporate sensors, advanced automation, real-time data analytics, and communication between equipment.

More than a technological shift, this is a mindset transformation. Systems must evolve from linear, reactive models to interconnected, adaptive, and data-driven ones. This transformation requires investments in digital skills, infrastructure modernization, and the integration of technology with Lean principles, ensuring that the focus on customer value, quality, and waste elimination remains central.

The impact of real-time OEE tracking on efficiency

Real-time monitoring of OEE (Overall Equipment Effectiveness) has proven to be a powerful tool for driving efficiency. By providing up-to-date data on equipment availability, performance, and quality, it enables fast, fact-based decision-making, immediate deviation detection, and more effective corrective actions.

OEE becomes more than a metric; it becomes an operational management platform when integrated with MES systems and predictive analytics solutions. Continuous visibility into asset and process status not only reduces losses but also promotes a culture of accountability and continuous improvement at the Gemba.

How sustainable production systems reduce emissions and waste

Sustainability is no longer a peripheral concern, but it has become a core criterion in shaping the production systems of the future. Sustainable systems not only minimize environmental impact but also improve economic efficiency and enhance corporate reputation with customers, investors, and regulators.

To achieve this standard, systems must be designed to minimize resource waste—raw materials, energy, and water—and systematically reduce emissions generated by operations. By applying Lean principles in combination with technologies such as smart consumption monitoring, energy automation, and green logistics, cleaner and more efficient production can be achieved, aligning with global sustainability goals. Producing better, with less impact, has become a strategic imperative.

Still have some questions about production system?

What should you know before implementing a production system?

Implementing a production system should not be seen as simply applying tools or isolated best practices. It is a structural transformation that requires preparation, strategic alignment, and leadership commitment. Before starting this journey, it’s essential to understand the system’s objectives, assess the current state of operations, and clearly define what the organization aims to achieve in terms of flow, quality, flexibility, and team engagement.

It is equally important to involve all levels of the organization from the very beginning. Promoting a culture centered on the Gemba (the place where value is created) ensures that leaders lead by example, practicing the principles they expect to see embedded across the organization. The success of implementation depends more on the consistency of routines and discipline in execution than on the complexity of the solutions adopted. An effective production system is built on stability, simplicity, and continuous improvement.

Which metrics best measure production system efficiency?

Measuring the efficiency of a production system requires careful selection of indicators that accurately reflect actual process performance. More than just collecting data, it’s essential that production metrics are aligned with the organization’s operational and strategic goals. Here are the main ones:

- Lead time: Total time from order receipt to delivery of the finished product.

- Service level: Percentage of orders delivered on time and in full, meeting customer specifications.

- Rework and defect rates: Measures quality at the source and the impact of process failures.

- Work in progress (WIP): Volume of in-process inventory is an indicator of process flow.

- OEE (Overall Equipment Effectiveness): Evaluates equipment effectiveness by combining availability, performance, and quality.

- Labor efficiency: Ratio between output produced and actual labor time invested.

The value of these metrics lies not in their measurement alone but in their daily use to detect deviations, drive improvements, and align teams with the production system’s objectives.

Lean vs. Traditional production systems

The primary difference between Lean and traditional production systems lies in how each defines efficiency and customer value. Traditional systems often prioritize maximizing resource utilization—keeping machines and labor constantly busy—even if it leads to inventory buildup, delays, or overproduction.

In contrast, Lean systems begin with flow. The goal is to deliver exactly what the customer needs, at the right time, with minimal waste. While traditional systems focus on large batch production, centralized planning, and reactive quality control, Lean systems emphasize one-piece flow, demand-driven production, quality built into the process, and daily improvement by frontline teams. This shift in approach reflects more than a new way of working; it demands a new way of thinking. At its core, the Lean system is a management model that puts people and value at the center of operations.

See more on Discrete Manufacturing

Find out more about transformation in this sector

See more on Manufacturing Operations

Find out more about improving this business area