The term Kaizen is often perceived as a synonym for small improvements. This perception has become deeply rooted in many organizations, and understandably so: small improvements are simple, accessible, and produce visible results. However, when Kaizen is reduced to just that, its true transformative power is lost.

This is where the paradox arises, since Kaizen also encompasses medium- and large-scale actions, such as Kaizen Events that redesign processes or strategic initiatives that align improvement efforts with major organizational goals. By limiting it to merely operational or incremental improvements, we overlook an enormous potential. This new perspective may seem counterintuitive at first. However, in reality, Kaizen has always been about continuous improvement, regardless of its scale.

In this article, we’ll explore one of the paradoxes of Kaizen Culture: “small is not the only Kaizen. We’ll understand how this change in mindset enables more disruptive, strategic, and integrated improvements.

What is a paradox?

A paradox is an idea that may seem contradictory—or even illogical—at first glance, but upon closer examination, it reveals a powerful truth. It’s precisely this tension between what seems to be and what really is that makes paradoxes so transformative. They challenge conventional thinking, force us to question established beliefs, and open space for new ways of seeing and acting.

The paradoxes of a continuous improvement culture

In the context of a continuous improvement culture, paradoxes play a central role. Many of the practices that drive real transformation defy traditional management logic. That’s why developing a Kaizen culture requires dealing with ideas that may initially seem incompatible, but in reality are not.

At Kaizen Institute, we’ve identified seven core paradoxes that help explain the principles of continuous improvement:

- Practice over tools

- Small is not the only Kaizen

- Efficiency begins with flow

- Standardize to improve

- Kaizen is more than operations

- Kaizen is a meta-strategy

- Kaizen is the smartest way to run a business

These paradoxes aren’t just theoretical concepts—they reflect the reality experienced by organizations trying to implement sustainable improvement. In our previous article, we explored the first paradox: practice over tools. Now, we turn to the second: small isn’t the only Kaizen, and why focusing only on small improvements may be limiting your organization’s true potential.

The old paradigm: Kaizen is about small improvements

For decades, the idea that Kaizen means making small, daily improvements has gained momentum around the world. This view gained popularity as an accessible and effective way to engage teams in solving everyday problems—without requiring significant investments or structural changes. Its simplicity was, for a long time, the key to its success.

However, this interpretation ultimately reduced the original meaning of Kaizen. In many organizations, it became synonymous with small improvements, overlooking its true potential as a philosophy of transformation. The result? An approach with limited impact.

Where did the idea that Kaizen means small improvements come from?

The association of Kaizen with small improvements has historical roots. After World War II, Japan underwent a significant industrial transformation, driven by Total Quality Control programs. During this period, Quality Circles (QC Circles) emerged, in which groups of operators gathered to suggest improvements in their work areas.

These movements were extremely effective at the time. They proved that anyone, regardless of their role, could contribute to process improvement. The concept of continuous improvement gained popularity rapidly. Books, consultants, and training programs helped spread the idea that Kaizen meant “improving every day through small actions.

This simplification served a purpose: it made the concept easy to understand and apply. However, by reducing Kaizen to an exclusively incremental practice, the business world lost sight of a fundamental aspect of its essence: the ability to also drive structural, profound, and strategic improvements.

Why small improvements don’t always solve the problem

Small improvements are valuable because they foster engagement, build trust, and contribute to a proactive work environment. However, when they’re the only approach used, they quickly reach their limit.

Many of the issues affecting organizational performance are structural, including poorly designed workflows, fragmented processes, or misaligned strategic decisions. These problems can’t be solved with isolated improvements. Reorganizing a warehouse shelf doesn’t fix an inefficient logistics process. Changing a form doesn’t streamline a slow decision-making process.

When everything is reduced to local, small-scale actions, the big picture is lost. Each team may improve its own area, but the interface problems between areas remain. And when results fail to materialize, frustration sets in: despite the effort, the real inefficiencies remain untouched.

What happened in many organizations is that Daily Kaizen, carried out by natural teams, became institutionalized as the only approach, and everything that escaped this model came to be treated as “projects.” Medium and large-scale improvements became disconnected from the Kaizen philosophy and were treated as exceptions. The outcome was an unbalanced system: improvements either too small to solve meaningful problems or too large to be part of the daily culture.

That’s why the paradigm needs to be rethought. True Kaizen is not limited to the small. It also lives in medium and large improvements, capable of transforming value chains and aligning improvement efforts with the organization’s strategic goals.

Are you facing structural problems that small improvements can’t solve?

The new paradigm: Small, medium, and large improvements in action

To effectively address real organizational challenges, it’s essential to understand Kaizen in its full scope: it includes small, medium, and large improvements, carried out every day, by everyone, and across all areas of the organization.

This new and broader paradigm recognizes that different types of problems require different types of improvements. When each is applied at the right time, by the right teams, the impact becomes truly transformative.

The Toyota example

One of the clearest examples of the new Kaizen paradigm comes from Toyota itself. The company’s deep transformation of its supply chain—through the implementation of the Toyota Production System (TPS)—was far more than a series of small improvements. It was a genuine breakthrough.

Transitioning from a forecast-driven, large-batch production model to a demand-driven system with one-piece flow required medium- and large-scale improvement initiatives involving multiple areas and decision-making levels. This advance would not have been possible with only small local improvements. It was the result of structured Kaizen Events, carried out with strategic vision and strong leadership commitment.

Toyota’s case demonstrates that continuous improvement, when effectively applied, has no limits to scale and can be the engine of a revolution in the management model.

The three levels of Kaizen and the Kaizen flag model

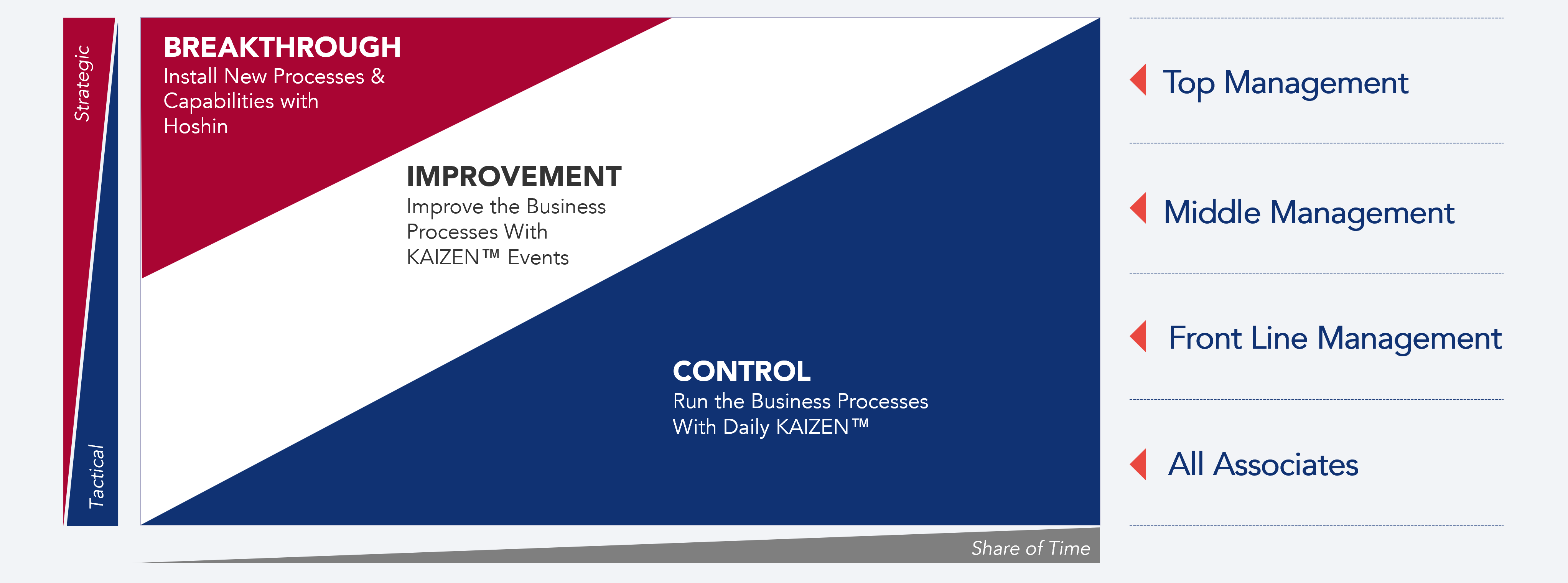

The new model introduces a structured approach to continuous improvement through three distinct levels, represented in the so-called Kaizen Flag:

- Daily KAIZEN™ (Blue): Small improvements carried out by frontline employees in their own work areas as part of their daily routine. These are quick, simple, and localized actions that help eliminate small amounts of waste and maintain process stability.

- KAIZEN™ Cycles (White): Structured improvements in Kaizen Events, led by cross-functional teams over a defined period (usually one week). These initiatives target more complex problems that affect entire processes or areas.

- Leaders’ KAIZEN™ (Red): Large-scale initiatives led by top management and embedded in the organization’s strategy using tools such as Hoshin Kanri. The goal is to achieve breakthroughs (disruptive improvements often with cross-functional or transformational impact).

Figure 1 – The Kaizen Flag, showing the three types of improvement spanning all organizational levels

This model was influenced by the teachings of J.M. Juran, who distinguished the different types of improvement within an organization. Kaizen integrates these types by engaging all hierarchical levels, making improvement a shared responsibility. Naturally, the time devoted to each type of improvement varies depending on the role and level of responsibility of each employee, as illustrated in the Kaizen Flag.

The impact of this new perspective

When organizations apply the three levels of Kaizen in a coordinated way, they can:

- Act across every layer of the organizational structure: Frontline employees improve their own work areas, supervisors lead teams through Kaizen Events, and managers drive strategic transformation.

- Address both operational issues and systemic challenges: From everyday problems to structural changes in value chains with real business impact.

- Avoid fragmented improvement efforts: Instead of dividing initiatives by scale or department, Kaizen becomes an integrated movement driven by a shared purpose.

- Provide clarity and a sense of purpose to teams: When everyone understands their role in improvement—regardless of their level—engagement grows, and the culture strengthens.

This new paradigm reintegrates Kaizen into the DNA of strategy, not just daily operations, transforming it into a true competitive advantage.

How to put this new approach into practice

Understanding that Kaizen includes small, medium, and large improvements is an important step. However, turning that vision into reality requires changes in habits, team engagement, and a strong commitment from leadership.

Clarify the true meaning of Kaizen

The first step is to clarify what Kaizen really means within the organization. Many teams still associate Kaizen solely with small operational improvements. It’s essential to build a shared language, one that explains the three types of improvement and the role each person plays in that process.

This alignment helps break down silos, eliminate misunderstandings, and reinforce that continuous improvement is an integral part of the organization’s culture, not the responsibility of a single department. When everyone understands what’s expected and how they can contribute, engagement naturally increases.

Organize Kaizen Events with cross-functional teams

Kaizen Events are a powerful tool for solving structural problems in an intensive, collaborative, and results-driven way. They should be planned regularly, involving people from different areas who understand the process and can make decisions.

A good starting point is to set an organizational target: for example, one Kaizen Event per year for every ten employees. These events promote hands-on learning, strengthen cross-functional collaboration, and show the value of going beyond small local improvements.

Connect strategy to improvement actions

To ensure Kaizen drives sustainable impact, it must be directly aligned with the organization’s strategic priorities. Tools such as Hoshin Kanri allow large objectives to be translated into specific and executable improvement projects.

In this model, leadership doesn’t delegate improvement; it actively practices it: guiding teams, removing roadblocks, and ensuring that Kaizen efforts directly support strategic outcomes. Improvement shifts from being random to being focused, coordinated, and directed toward what truly matters.

Is your approach to continuous improvement aligned with your organization’s strategy?

Measuring and recognizing all types of improvement

It’s essential to measure all forms of improvement, not just the number of suggestions made and implemented, but also the impact of major transformations. Indicators should be defined that reflect the contribution of small, medium, and large actions.

Equally important is publicly recognizing the efforts of both operators who improve their workplace and teams that lead strategic events or initiatives. Valuing effort and impact helps to consolidate a culture where everyone experiences continuous improvement.

Conclusion: A true Kaizen culture goes far beyond small improvements

Reducing Kaizen to small daily improvements is an incomplete and limiting view. While these actions are essential to keeping the spirit of improvement alive, they alone are not enough to transform an organization. Today’s challenges demand a broader, more integrated approach.

An authentic Kaizen culture is one that combines all types of improvement—small, medium, and large—in a coordinated, ongoing way. It’s a culture where every level of the organization has a defined role. And it’s one where improvement is tightly connected to strategy, ensuring every effort contributes to a greater purpose.

The focus should be on having top management improve and deploy strategies while fostering a Kaizen culture. Middle management should lead Kaizen Events to optimize processes, and frontline teams should ensure daily control and problem-solving through Daily Kaizen.

When Kaizen is practiced at all scales, by everyone, and across every area, it becomes an intelligent management model—a true engine of transformation toward operational excellence and a lasting competitive advantage.

Article based on the book The Kaizen Culture Paradox – The Smartest Way to Run a Business by Alberto Bastos and Euclides Coimbra (coming soon).

See more on People & Culture

Find out more about improving your organization